NANJING ALAS INTERNATIONAL CO., LTD

Nanjing, China

L/C, T/T, Money Gram

| Availability: | |

|---|---|

| Quantity: | |

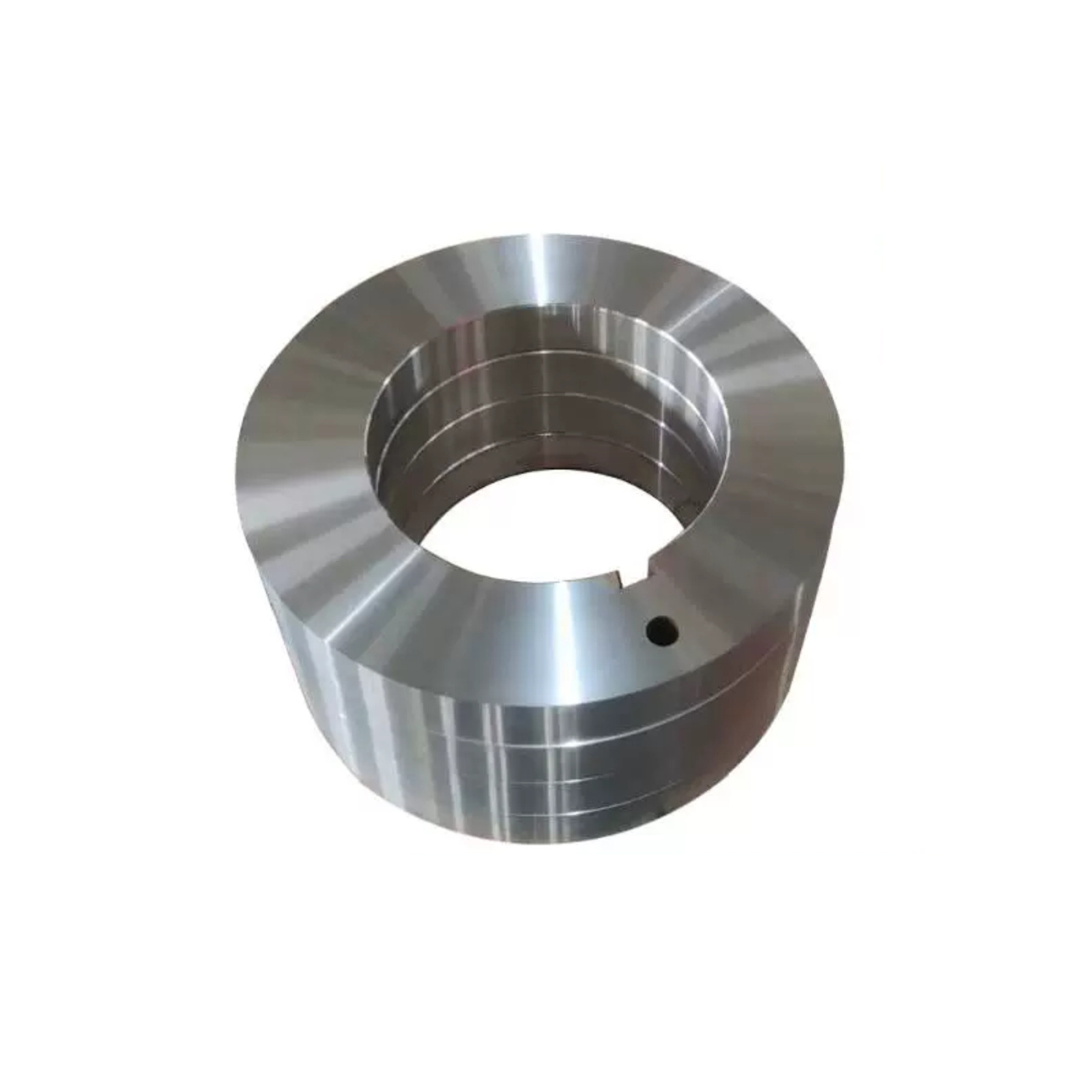

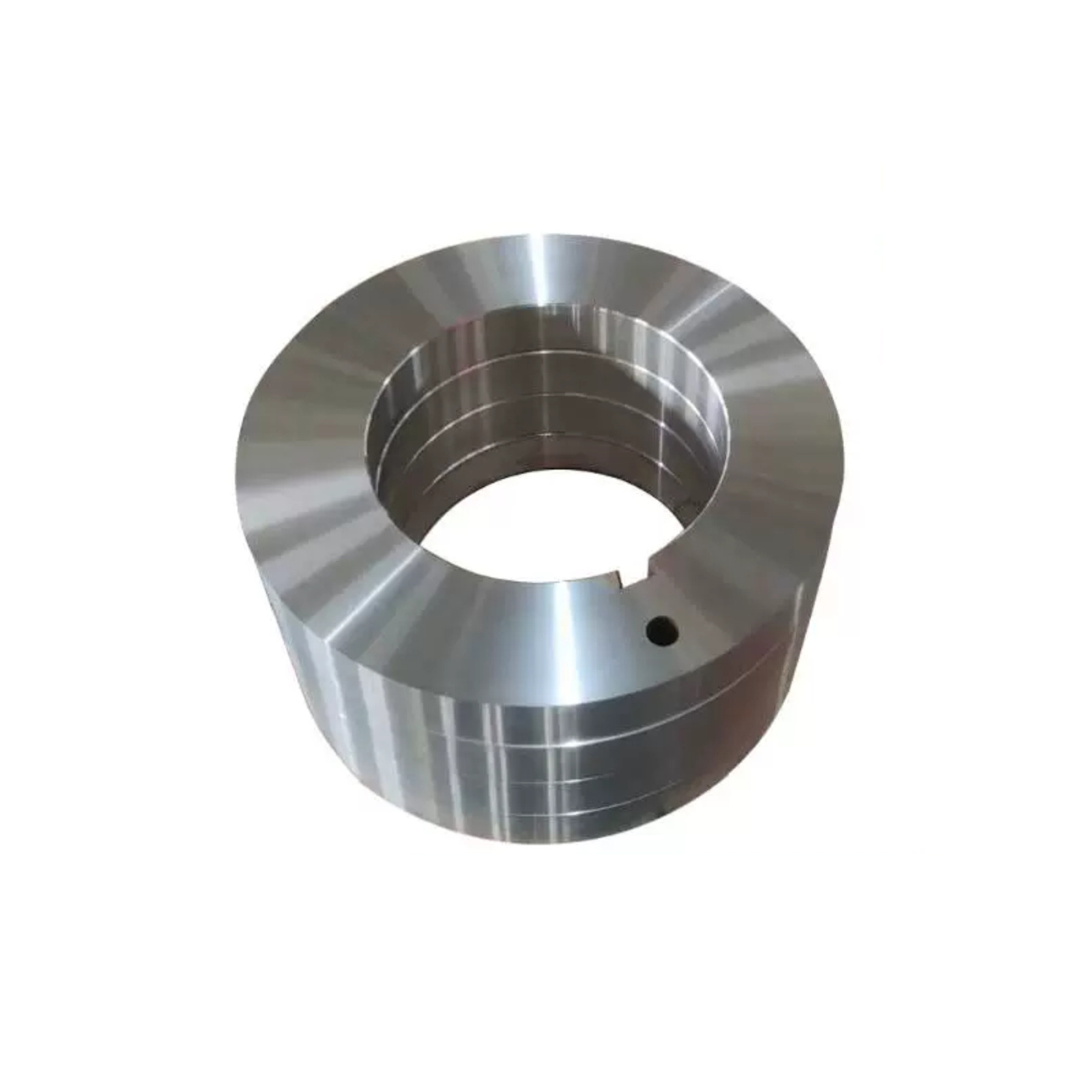

Slitting machine blades are the core precision cutting tools in metal sheet slitting production lines. They are mainly used to precisely cut wide metal coils such as steel strips, stainless steel strips, aluminum strips, and copper strips into narrow strips of customized widths according to requirements. They are essential tools for deep processing of metal coils in industries such as metallurgy, metal processing, automotive parts, home appliances, and hardware. Their precision directly determines the flatness of the cut edges, the burr-free effect, and the production efficiency of the slitting process.

Made from high-quality base materials such as Cr12MoV, SKD11, high-speed steel, and cemented carbide, and经过 professional heat treatment including vacuum quenching and deep cryogenic treatment, the blades achieve a Rockwell hardness of HRC58-62. The cutting edge can be optionally strengthened with nitriding or TiN coating, providing wear resistance and impact resistance, significantly reducing the frequency of blade changes and lowering production costs.

The cutting edge tolerance is controlled at the micron level, and the runout and end face runout geometric tolerances are strictly controlled. After slitting, the coil edges are flat, without curling or burrs, eliminating the need for subsequent secondary processing and improving the production efficiency of downstream processes.

The outer diameter, inner diameter, thickness, and cutting edge angle of the blades can be customized according to the material, thickness, and width of the slitting material, adapting to various models of slitting machines. Customization of circular and irregularly shaped slitting machine blades, as well as upper and lower blade sets, is supported to meet the needs of different processing scenarios.

The blades undergo uniform overall heat treatment with minimal deformation. During high-speed slitting, there is no wobbling and the operation is stable, ensuring the consistency of the narrow strip slitting dimensions, effectively avoiding product scrap and improving coil utilization.

The most widely used standard type, with a disc-shaped structure. Multiple blades can be adjusted to achieve different cutting widths, suitable for conventional large-scale slitting of most metal coils such as steel strips, aluminum strips, and ordinary stainless steel strips.

Custom-designed with special structures such as stepped or beveled edges, specifically designed for difficult-to-process materials such as thick metal coils, hard alloy coils, and special alloy strips, meeting the needs of special slitting machines and high-precision slitting.

Specifically designed according to the installation position of the slitting machine, used in conjunction to form a precise cutting pair, ensuring uniform cutting force. This is a basic standard configuration for all types of slitting machines and is suitable for slitting all specifications of metal coils.

Steel mills and aluminum plants use these blades for large-scale fixed-width slitting of hot-rolled/cold-rolled steel strips, aluminum coils, and stainless steel coils before shipment, meeting the needs of large-batch coil processing.

Sheet metal processing companies use these blades for secondary deep processing and slitting of various metal coils, customizing narrow-width coils as needed to meet the personalized size requirements of downstream customers.

Provides precision narrow-width metal strip slitting for the production of automotive stamping parts, home appliance casings, and hardware accessories, ensuring the processing accuracy of the final product.

For surface-treated or special metal coils such as galvanized strips, color-coated strips, copper strips, and titanium strips, high-precision slitting is achieved, ensuring both cutting quality and surface protection of the material.

Material Selection: Primarily high-toughness alloy tool steel/high-speed steel, with high-end models using cemented carbide, ensuring the basic performance of the blades from the source;

Professional Heat Treatment: Vacuum quenching, uniform hardness distribution, improved core toughness, preventing chipping and breakage;

Precision CNC Machining: Fine machining with CNC lathes and grinding machines, strict tolerance control, ensuring assembly and slitting accuracy;

Customized Cutting Edge: Small-angle cutting edge for thin materials, large-angle cutting edge for thick/hard materials, precision grinding and polishing for smooth, burr-free slitting;

Surface Strengthening: Nitriding and TiN coating treatment to improve surface hardness, reduce friction coefficient, and minimize material sticking to the blade.

Before installation, check that the cutting edge is free of chipping and burrs, ensure the coaxiality of the blade and the spindle, and tighten securely to prevent wobbling and loosening during high-speed operation;

Precisely adjust the blade spacing and cutting gap according to the material and thickness of the slitting material. Too large a gap can cause burrs, while too small a gap increases wear;

Clean metal chips promptly during operation to avoid scratching the cutting edge; apply rust prevention treatment to idle blades, store them in a dry and flat place, and avoid collisions;

Source Manufacturer: Own production workshop, complete CNC machining equipment, support for customized orders, and controllable delivery time;

Quality Assurance: Full-process quality inspection, from material selection to finished products, ensuring blade accuracy and wear resistance;

Full Specification Compatibility: Covering round, irregular, upper/lower blades, compatible with all models of slitting machines, meeting the processing needs of different industries;

After-Sales Support: Providing one-stop service including blade selection, installation guidance, and precision grinding and repair, solving processing problems.

Slitting machine blades are the core precision cutting tools in metal sheet slitting production lines. They are mainly used to precisely cut wide metal coils such as steel strips, stainless steel strips, aluminum strips, and copper strips into narrow strips of customized widths according to requirements. They are essential tools for deep processing of metal coils in industries such as metallurgy, metal processing, automotive parts, home appliances, and hardware. Their precision directly determines the flatness of the cut edges, the burr-free effect, and the production efficiency of the slitting process.

Made from high-quality base materials such as Cr12MoV, SKD11, high-speed steel, and cemented carbide, and经过 professional heat treatment including vacuum quenching and deep cryogenic treatment, the blades achieve a Rockwell hardness of HRC58-62. The cutting edge can be optionally strengthened with nitriding or TiN coating, providing wear resistance and impact resistance, significantly reducing the frequency of blade changes and lowering production costs.

The cutting edge tolerance is controlled at the micron level, and the runout and end face runout geometric tolerances are strictly controlled. After slitting, the coil edges are flat, without curling or burrs, eliminating the need for subsequent secondary processing and improving the production efficiency of downstream processes.

The outer diameter, inner diameter, thickness, and cutting edge angle of the blades can be customized according to the material, thickness, and width of the slitting material, adapting to various models of slitting machines. Customization of circular and irregularly shaped slitting machine blades, as well as upper and lower blade sets, is supported to meet the needs of different processing scenarios.

The blades undergo uniform overall heat treatment with minimal deformation. During high-speed slitting, there is no wobbling and the operation is stable, ensuring the consistency of the narrow strip slitting dimensions, effectively avoiding product scrap and improving coil utilization.

The most widely used standard type, with a disc-shaped structure. Multiple blades can be adjusted to achieve different cutting widths, suitable for conventional large-scale slitting of most metal coils such as steel strips, aluminum strips, and ordinary stainless steel strips.

Custom-designed with special structures such as stepped or beveled edges, specifically designed for difficult-to-process materials such as thick metal coils, hard alloy coils, and special alloy strips, meeting the needs of special slitting machines and high-precision slitting.

Specifically designed according to the installation position of the slitting machine, used in conjunction to form a precise cutting pair, ensuring uniform cutting force. This is a basic standard configuration for all types of slitting machines and is suitable for slitting all specifications of metal coils.

Steel mills and aluminum plants use these blades for large-scale fixed-width slitting of hot-rolled/cold-rolled steel strips, aluminum coils, and stainless steel coils before shipment, meeting the needs of large-batch coil processing.

Sheet metal processing companies use these blades for secondary deep processing and slitting of various metal coils, customizing narrow-width coils as needed to meet the personalized size requirements of downstream customers.

Provides precision narrow-width metal strip slitting for the production of automotive stamping parts, home appliance casings, and hardware accessories, ensuring the processing accuracy of the final product.

For surface-treated or special metal coils such as galvanized strips, color-coated strips, copper strips, and titanium strips, high-precision slitting is achieved, ensuring both cutting quality and surface protection of the material.

Material Selection: Primarily high-toughness alloy tool steel/high-speed steel, with high-end models using cemented carbide, ensuring the basic performance of the blades from the source;

Professional Heat Treatment: Vacuum quenching, uniform hardness distribution, improved core toughness, preventing chipping and breakage;

Precision CNC Machining: Fine machining with CNC lathes and grinding machines, strict tolerance control, ensuring assembly and slitting accuracy;

Customized Cutting Edge: Small-angle cutting edge for thin materials, large-angle cutting edge for thick/hard materials, precision grinding and polishing for smooth, burr-free slitting;

Surface Strengthening: Nitriding and TiN coating treatment to improve surface hardness, reduce friction coefficient, and minimize material sticking to the blade.

Before installation, check that the cutting edge is free of chipping and burrs, ensure the coaxiality of the blade and the spindle, and tighten securely to prevent wobbling and loosening during high-speed operation;

Precisely adjust the blade spacing and cutting gap according to the material and thickness of the slitting material. Too large a gap can cause burrs, while too small a gap increases wear;

Clean metal chips promptly during operation to avoid scratching the cutting edge; apply rust prevention treatment to idle blades, store them in a dry and flat place, and avoid collisions;

Source Manufacturer: Own production workshop, complete CNC machining equipment, support for customized orders, and controllable delivery time;

Quality Assurance: Full-process quality inspection, from material selection to finished products, ensuring blade accuracy and wear resistance;

Full Specification Compatibility: Covering round, irregular, upper/lower blades, compatible with all models of slitting machines, meeting the processing needs of different industries;

After-Sales Support: Providing one-stop service including blade selection, installation guidance, and precision grinding and repair, solving processing problems.