Core Logic: Slitting Quality = Blade Material Matching + Machining Accuracy + Heat Treatment Process + Component Synergy, all four are indispensable.

Core Material Matching: Precise Selection Based on Slitting Material

Choosing the wrong material is the primary reason for burrs, chipping, and material sticking during slitting. It must strictly correspond to the material being processed:

Slitting Cold-Rolled Steel and Galvanized Steel

Recommended Materials: Cr12MoV, D2, SKD-11

Core Advantages: High-wear-resistant general-purpose material, suitable for high-speed continuous slitting conditions, long-lasting sharpness, effectively controls burrs on the strip edges, and offers the best balance of cost-effectiveness and durability.

Slitting Stainless Steel and High-Strength Steel (AHSS)

Recommended Materials: LD (7Cr7Mo2V2Si) / H13 (4Cr5MoSiV1)

Core Advantages: Stainless steel has strong work hardening characteristics, and ordinary D2 is prone to micro-chipping; LD material combines high toughness and anti-adhesion properties, preventing material sticking to the blade edge; H13 is suitable for heavy-duty slitting scenarios and has excellent impact fatigue resistance.

Slitting Silicon Steel Sheets, Copper and Aluminum Foils (Ultra-Thin Precision Strips)

Recommended Materials: Tungsten Carbide (Cemented Carbide) / ASP-23 Powder High-Speed Steel

Core Advantages: The mainstream solution for precision slitting in 2026, with a hardness of up to HRA 88-92 (tungsten carbide) / HRC 64-68 (powder steel), enabling burr-free ultra-precision cutting, and a service life more than 10 times that of ordinary tool steel.

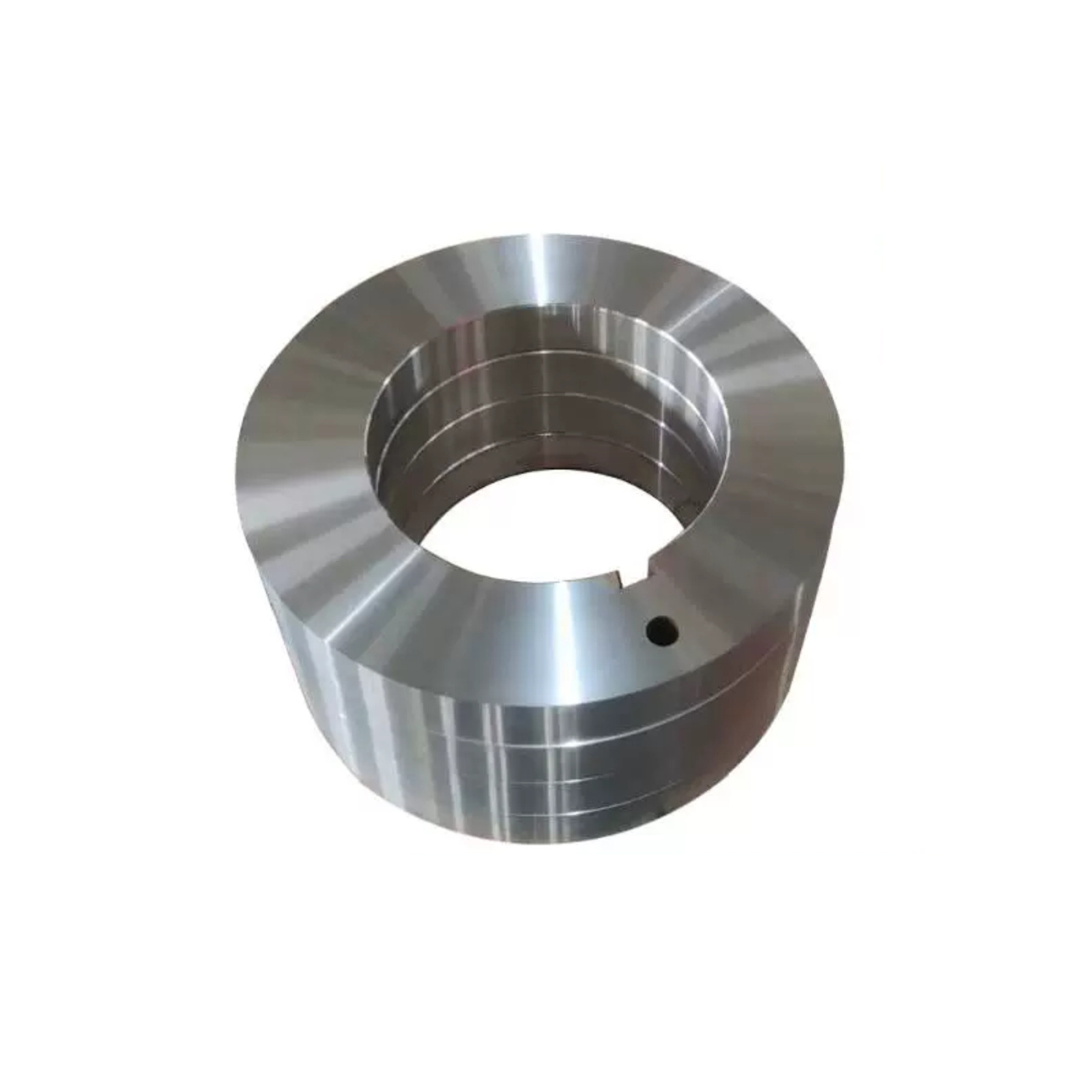

Machining Accuracy Indicators: Essential Core Parameters (Errors must not accumulate)

The accuracy of the slitting blade directly determines the strip width tolerance and edge flatness. Suppliers must meet the following standards during selection:

Thickness Tolerance

Must reach ±0.001mm, otherwise, errors will accumulate when multiple blades are combined, causing the total strip width to deviate from the requirements.

Parallelism

Should be controlled within 0.002mm to avoid wavy edges on the slit strip, affecting subsequent processing and use.

Surface Roughness (Blade Edge Side)

Must reach mirror-grade (Ra < 0.1μm), otherwise it will increase lateral friction, causing metal powder to adhere to the blade edge, leading to secondary scratching of the strip material.

Heat Treatment and Surface Treatment: Determining the Lower Limit of Blade Performance

Material is the foundation, and heat treatment process directly affects the dimensional stability and service life of the blade:

Overall Vacuum Heat Treatment (Mandatory Requirement)

Function: Ensures uniform hardness of the blade from inside to outside, preventing slight wobbling due to uneven hardness during high-speed rotation, thus damaging the spindle and affecting slitting accuracy.

DLC Diamond-like Coating (Optional)

Applicable Scenarios

Slitting aluminum plates and color-coated plates

Function

Significantly reduces the friction coefficient of the blade surface, preventing aluminum adhesion and coating peeling, maintaining a clean and stain-free cut.

Quick Selection Guide

Ultra-Thin Strips (Below 0.5mm)

Applicable Materials: Silicon steel, copper and aluminum foil

Recommended Blades: Powder steel or tungsten steel

Hardness Requirements: HRC 64-68 (powder steel), HRA 90 (tungsten steel)

Core Focus: Extremely sharp edges and zero burrs

Ordinary Plates (1.0-3.0mm)

Applicable Materials: Cold-rolled plates, galvanized plates

Recommended Blades: Cr12MoV (D2)

Hardness Requirements: HRC 58-61

Core Focus: High wear resistance and cost-effectiveness

High-Strength Steel

Applicable Materials: Automotive AHSS

Recommended Blades: LD or DC53

Hardness Requirements: HRC 60-63

Core Focus: Impact resistance and anti-micro-chipping

Hot-Rolled Plates (Heavy-Duty Slitting)

Recommended Blades: 6CrW2Si or H13

Hardness Requirements: HRC 54-58

Core Focus: Toughness and heat fatigue resistance

Expert Advice: Accessories are the "Invisible Key" to Slitting Quality

50% of slitting quality depends on the blade, and 50% depends on the synergy of spacers and rubber rings.

Spacers

The accuracy must be exactly the same as the blade (±0.001mm), otherwise it will lead to excessive spindle clearance and exceeding the slitting width deviation.

Rubber Rings

We recommend using high-elastic polyurethane material, which combines strong material ejection function with surface protection, preventing indentations and scratches on the surface of the strip material.