NANJING ALAS INTERNATIONAL CO., LTD

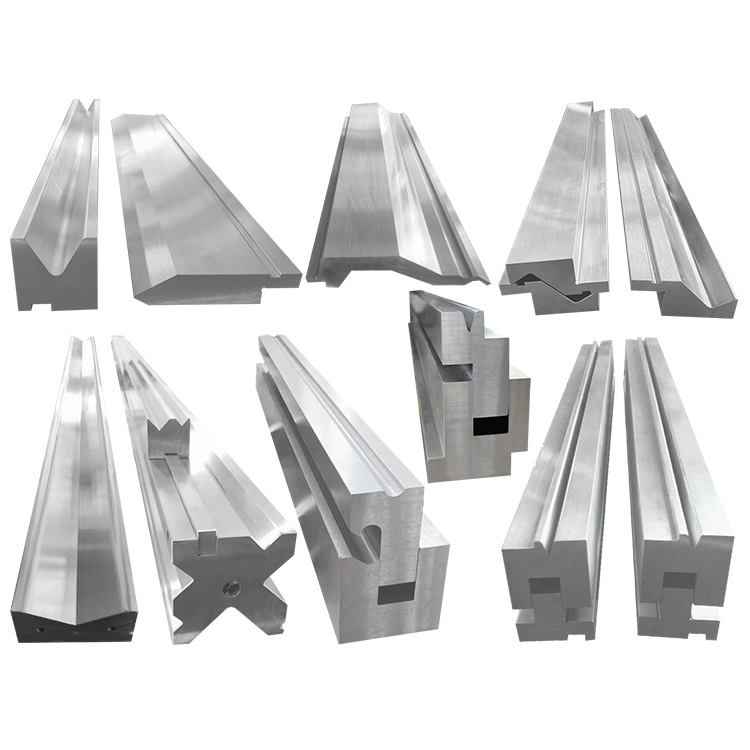

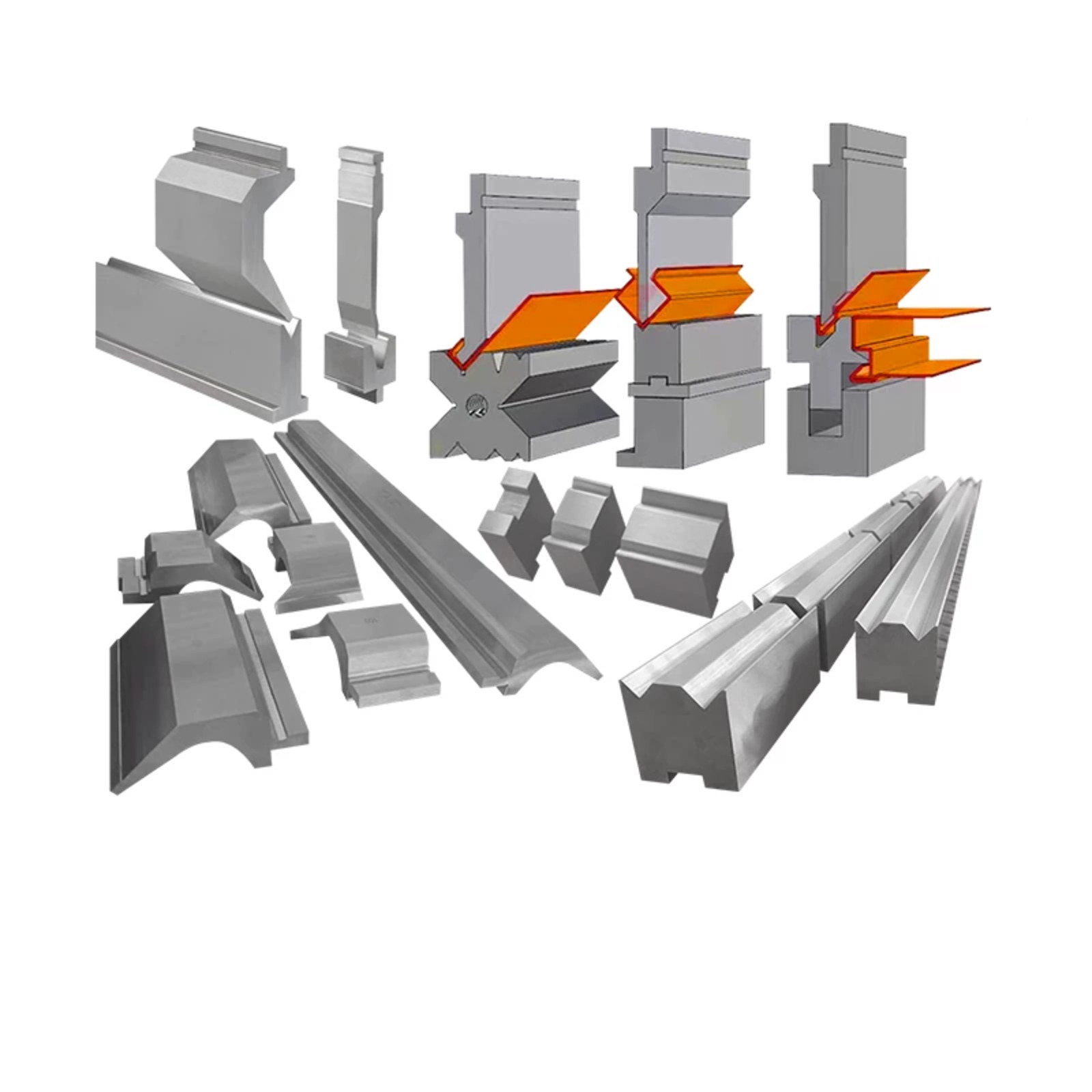

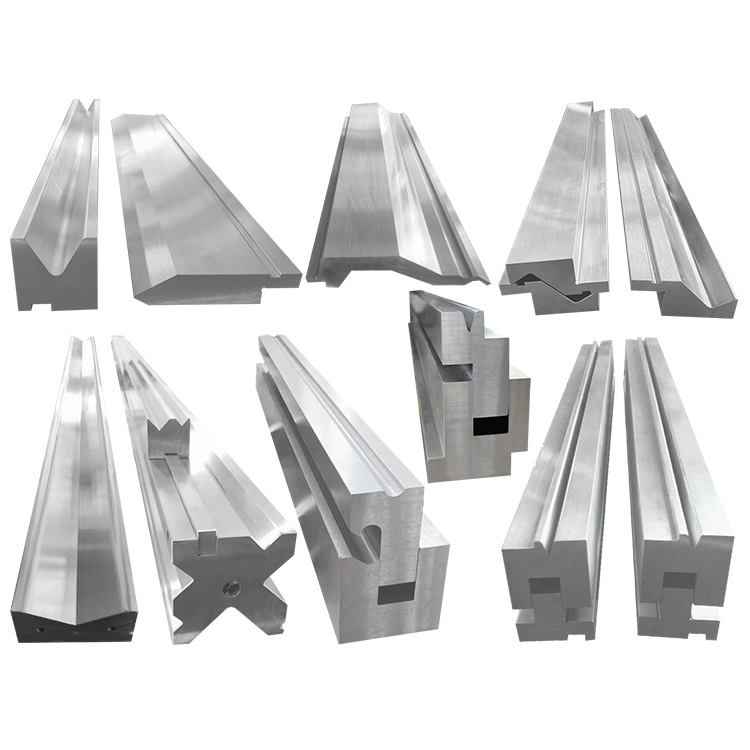

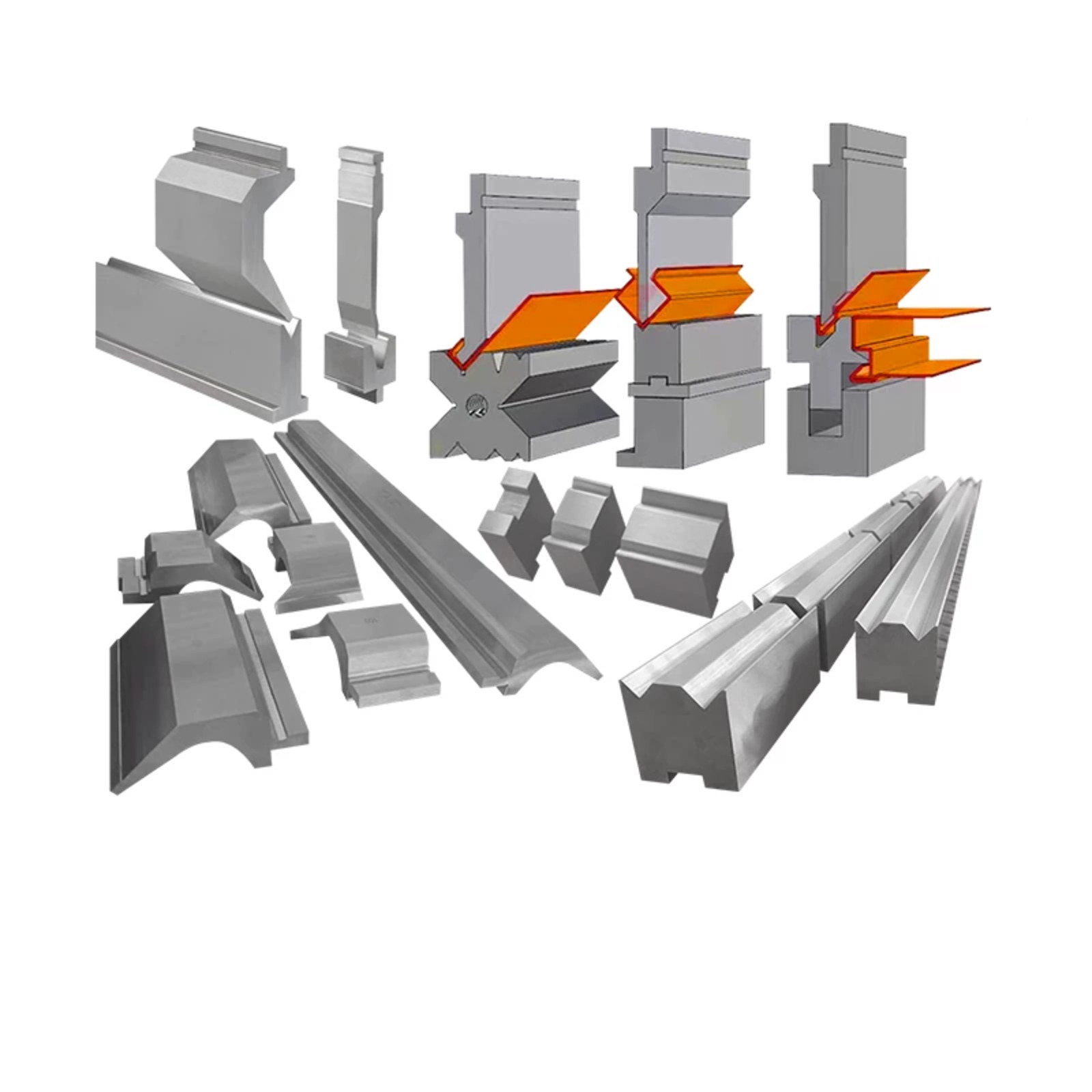

press brake tooling are specialized forming molds used in conjunction with bending machines. They are the core working components for bending and forming metal sheets, mainly composed of two key parts: the upper die and the lower die. Through the relative movement of the bending machine's slider and workbench, the metal sheet is squeezed between the upper and lower dies, causing deformation and bending it into a workpiece of a specified angle, shape, and size (such as 90° right angle, U-shape, V-shape, etc.). They are widely used in sheet metal processing fields such as mechanical manufacturing, sheet metal fabrication, hardware production, and cabinet manufacturing.

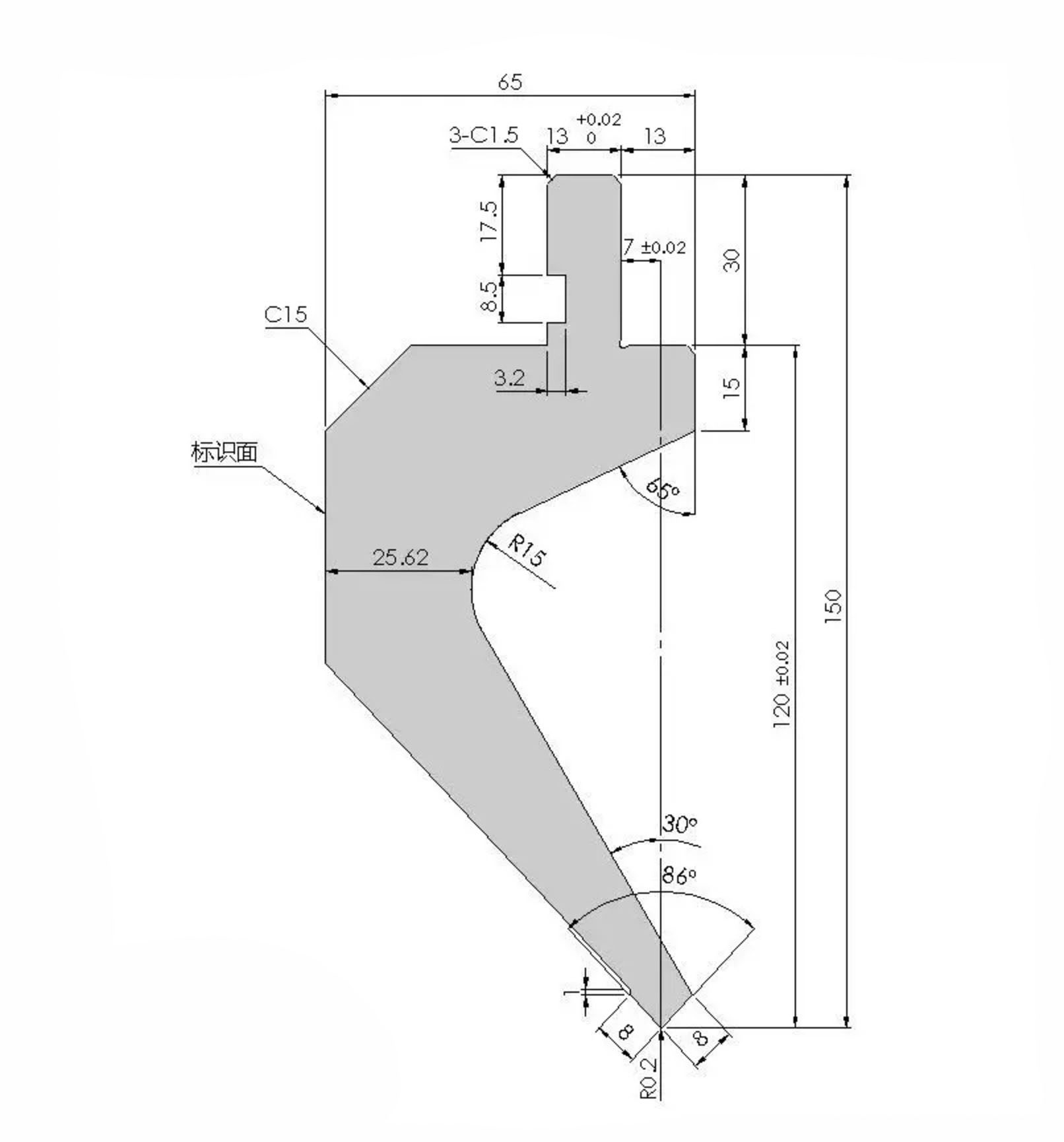

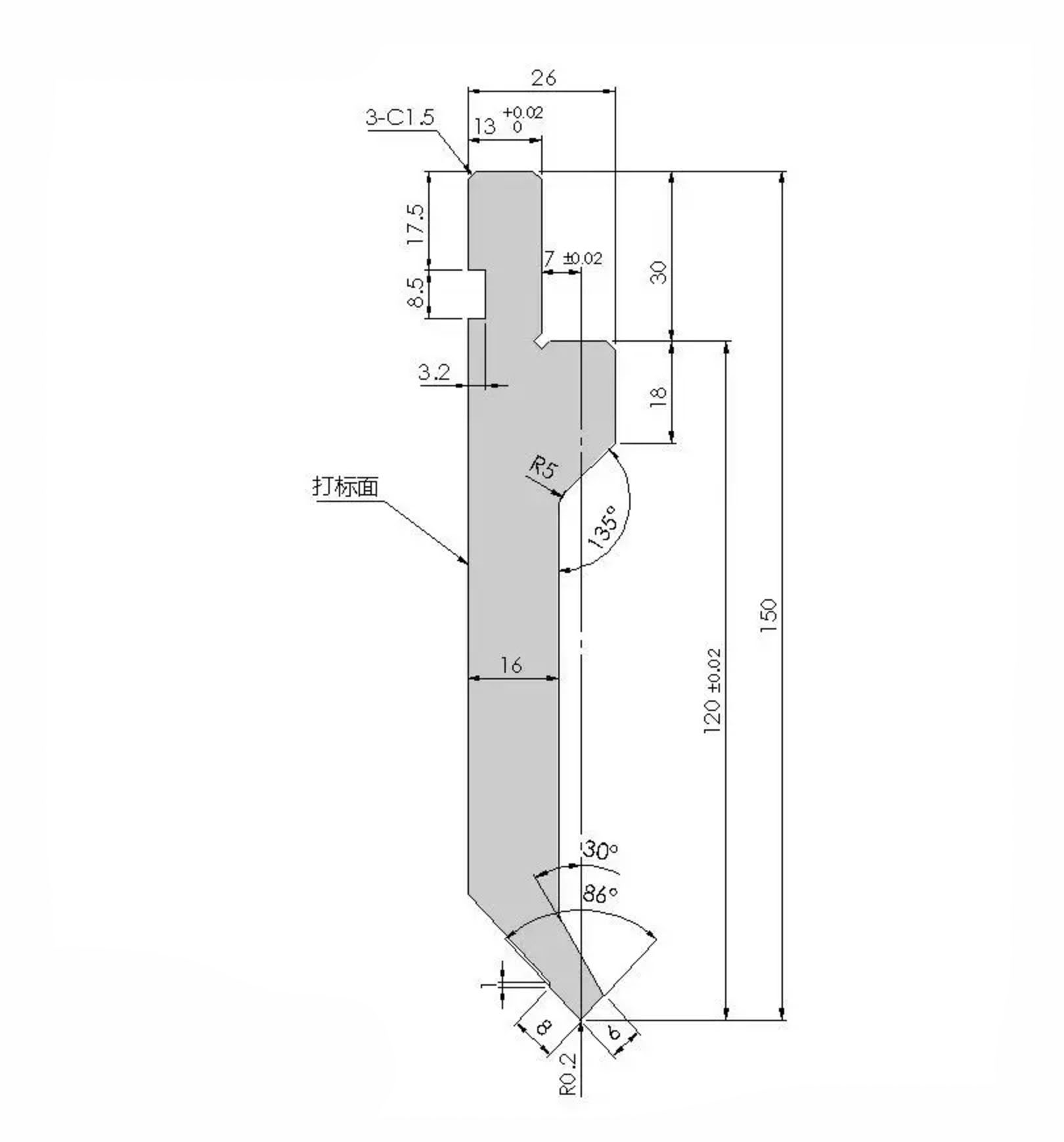

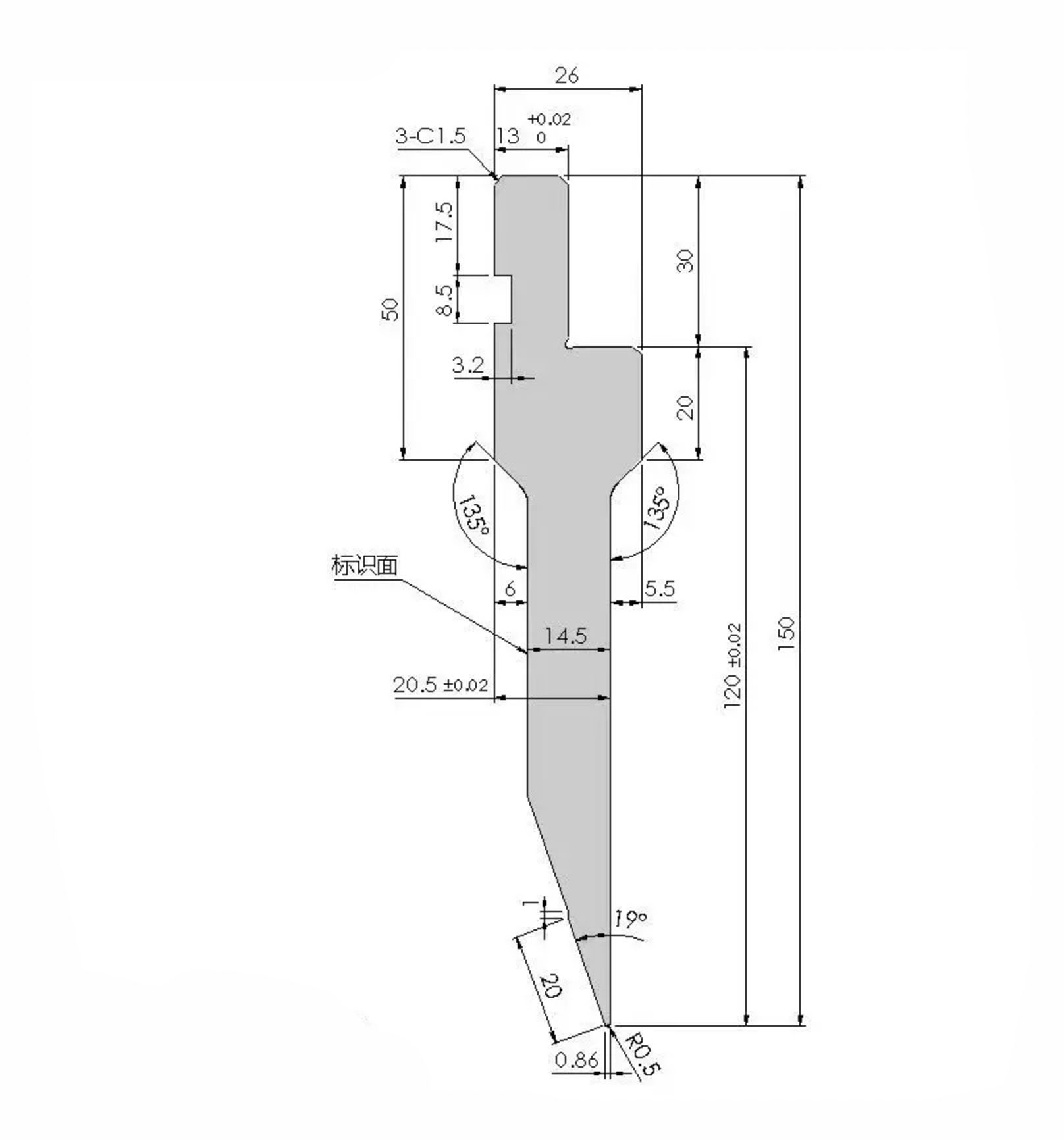

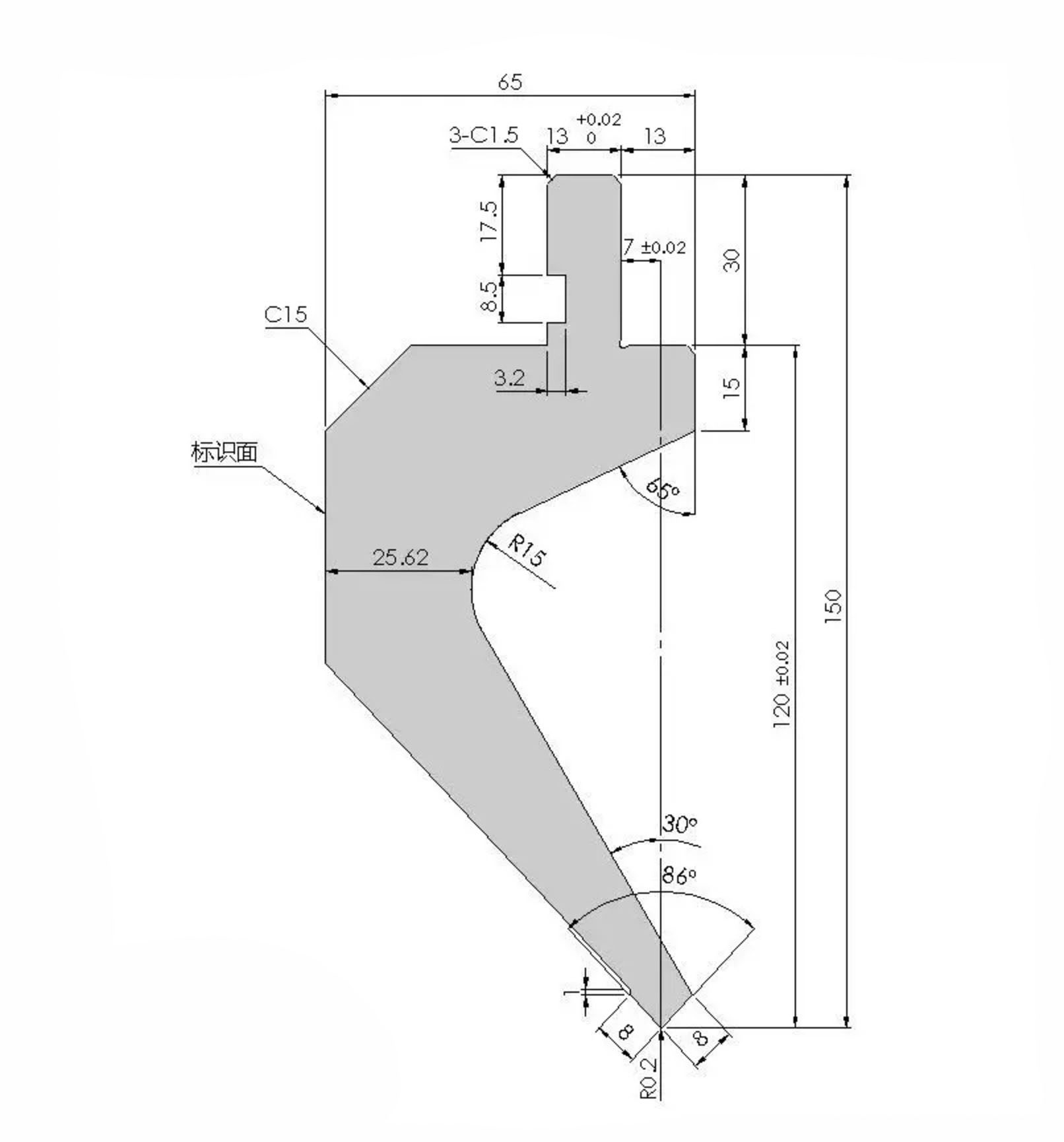

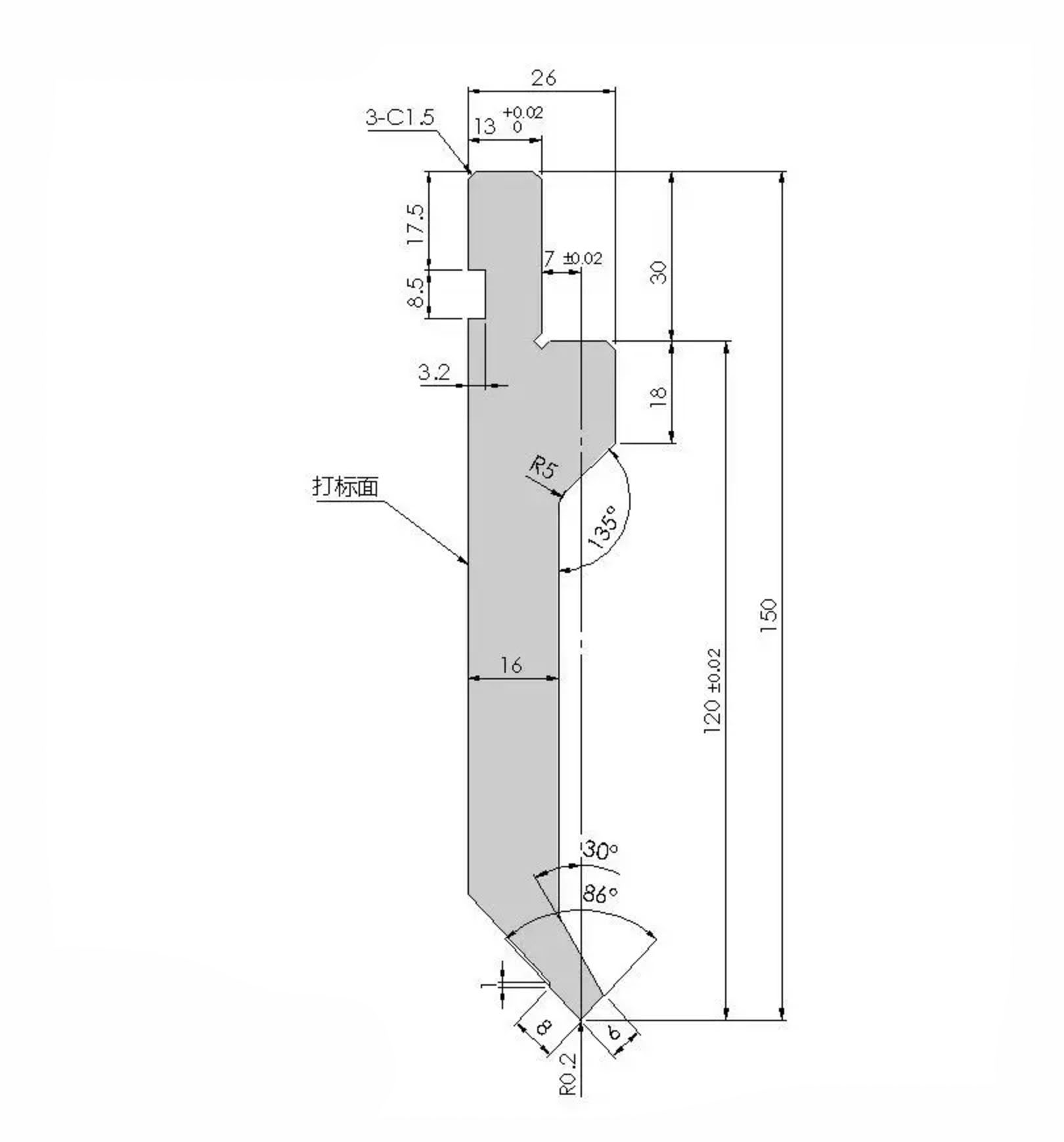

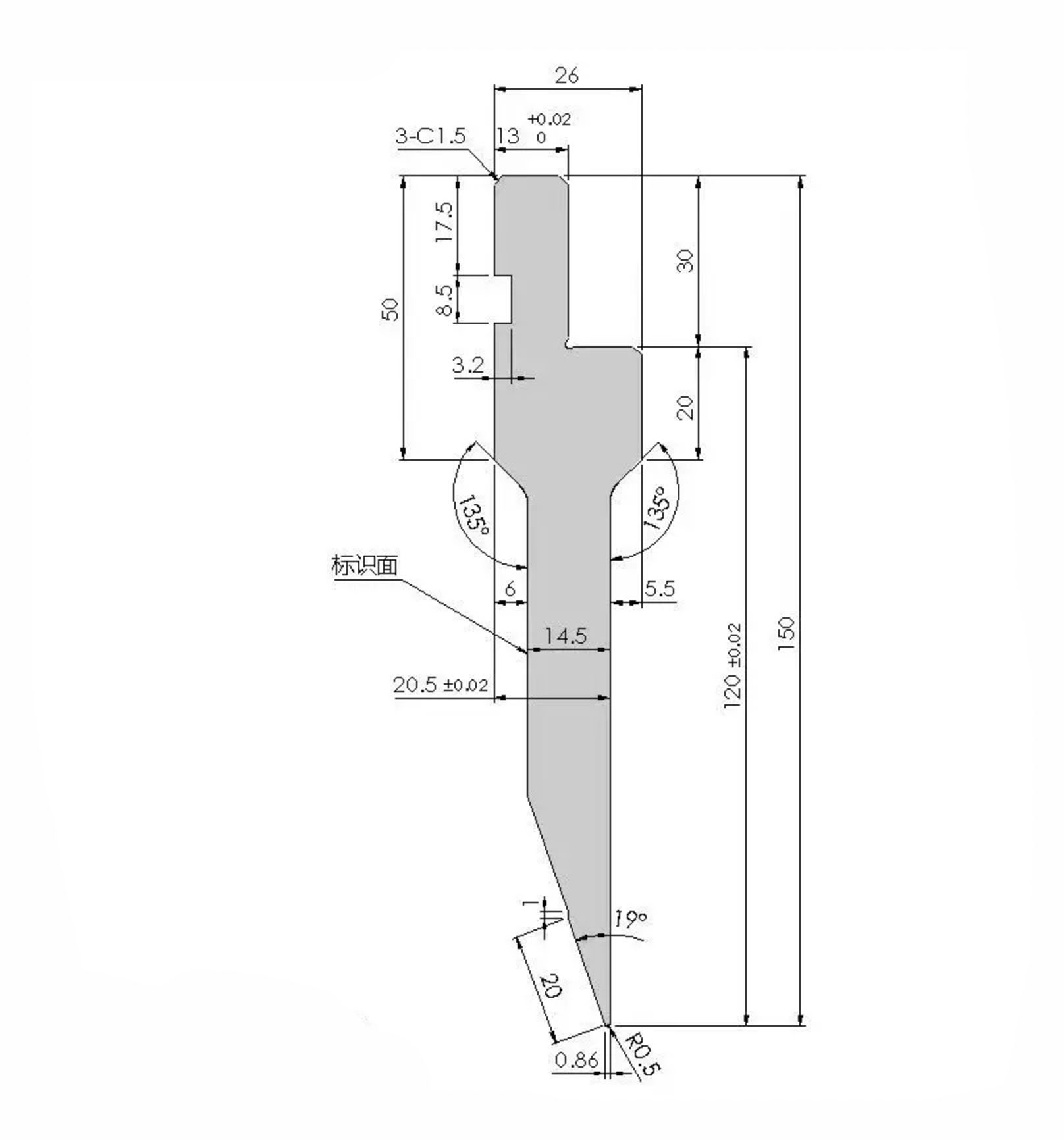

: Installed on the movable slider of the bending machine, it is the active pressure-applying component. Its shape (standard straight edge, sharp corner, gooseneck, arc, etc.) determines the outer contour of the bent part of the workpiece;

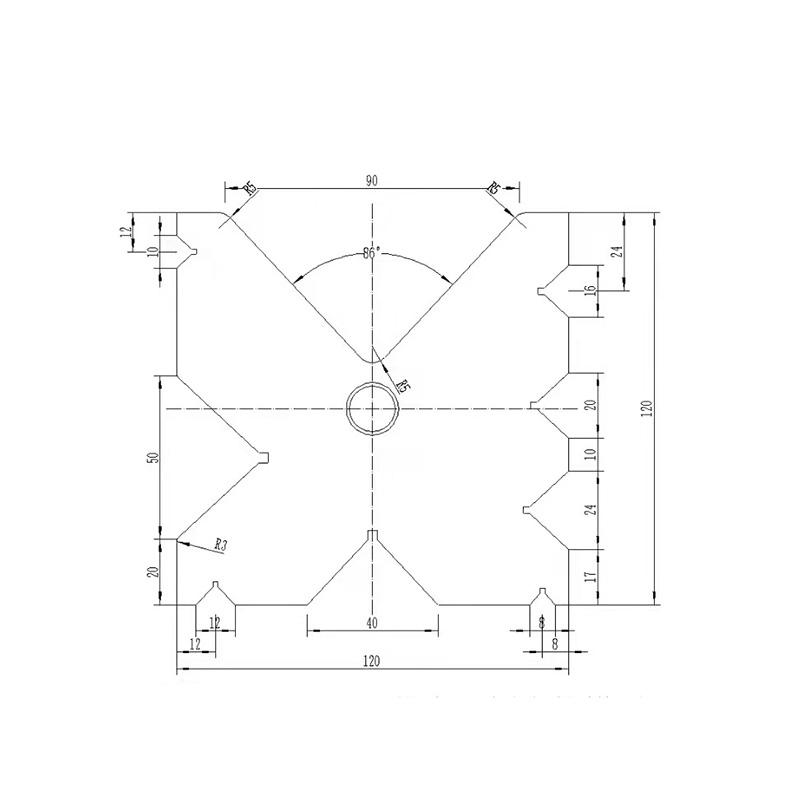

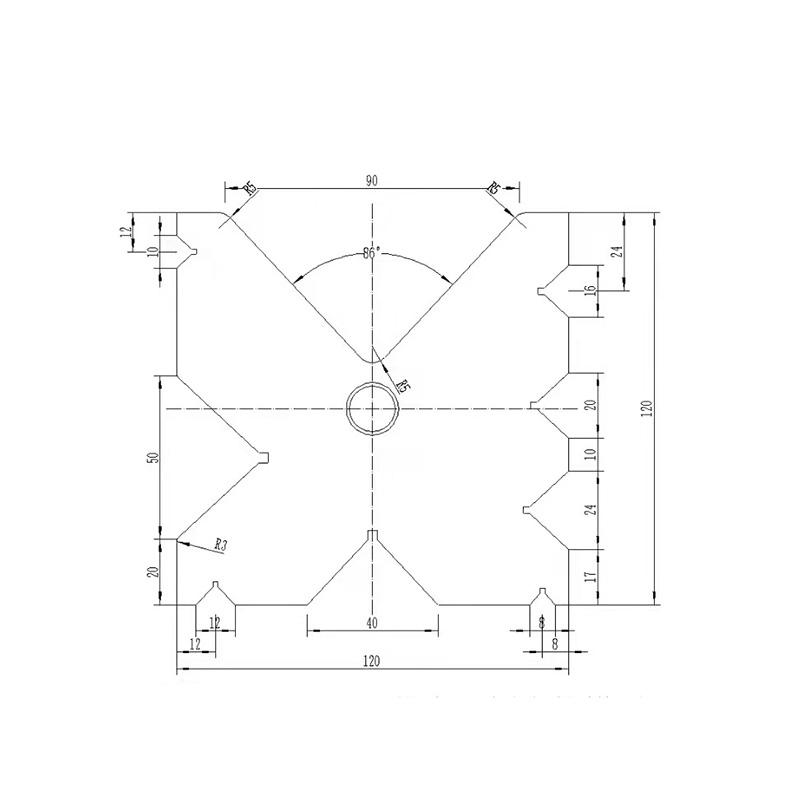

: Fixed on the workbench of the bending machine, it is the fixed support component, mainly using a V-shaped groove (V-groove) as its structure. The width of the V-groove directly affects the bending force, fillet size, and forming effect of the sheet metal;

: The metal sheet is placed on the lower die, and the slider drives the upper die to press down vertically. The sheet is forced to conform to the contours of the upper and lower dies and undergoes irreversible plastic deformation. After reaching the preset stroke and pressure, the bending and forming are completed. After forming, the upper die returns to its original position, and the workpiece can be removed.

: The main material is alloy structural steel (such as 42CrMo), processed through heat treatment processes such as tempering and quenching, ensuring sufficient hardness (generally HRC45-HRC50), load-bearing capacity, and wear resistance to withstand the enormous extrusion force and friction during the bending process;

: According to the different bending requirements of the workpiece (angle, shape, size, material thickness), the punch can be customized into special shapes such as arc, gooseneck, and irregular shapes, and the die can be processed into V-grooves of different widths (such as 8mm, 16mm, 24mm) or special groove types;

: The specifications of the mold (height, shank type, installation size) must be fully compatible with the clamping system, slider stroke, and rated tonnage of the bending machine; the forming dimensions must be consistent with the workpiece drawing requirements to ensure bending accuracy and pass rate;

: Conventional bending machine molds have general standard specifications (matching common bending machine brands such as Amada, Trumpf, and Wille), and can be purchased and used directly; special molds can be customized according to the actual processing needs of the enterprise.

: Suitable for conventional straight edge bending, the most widely used;

: Suitable for small angle bending or springback compensation, meeting the needs of high-precision sharp angle forming;

: Suitable for U-shaped grooves and deep channel workpiece processing, which can avoid the already bent edges of the workpiece and prevent interference;

: Suitable for arc and rounded corner bending and forming, such as arc-shaped workpieces and transition rounded corner processing;

: Customized according to special workpiece drawings, suitable for bending requirements of irregular shapes.

: Suitable for ordinary sheet metals such as low-carbon steel and galvanized steel, offering high cost-effectiveness;

: Thickened design and high-hardness materials, suitable for difficult-to-bend materials such as stainless steel and high-strength alloy plates;

: Precision machined to prevent warping, deformation, and scratching during the bending of thin materials.

Amada/Promecam Type: Compatible with the clamping system of Amada series bending machines;

Trumpf/Wila Type: Compatible with the clamping system of Trumpf and Wila series bending machines;

New Standard Type: Universal interface, suitable for most domestic bending machines.

Selecting the right press brake tooling is crucial for ensuring bending accuracy, production efficiency, and die service life.

The key points for selecting press brake tooling are matching material characteristics, bending processes, workpiece requirements, and equipment parameters—none of which can be dispensed with. The following five key points cover all critical technical aspects of the entire selection process, ensuring both bending accuracy and die life. Beginners can directly refer to them for precise selection.

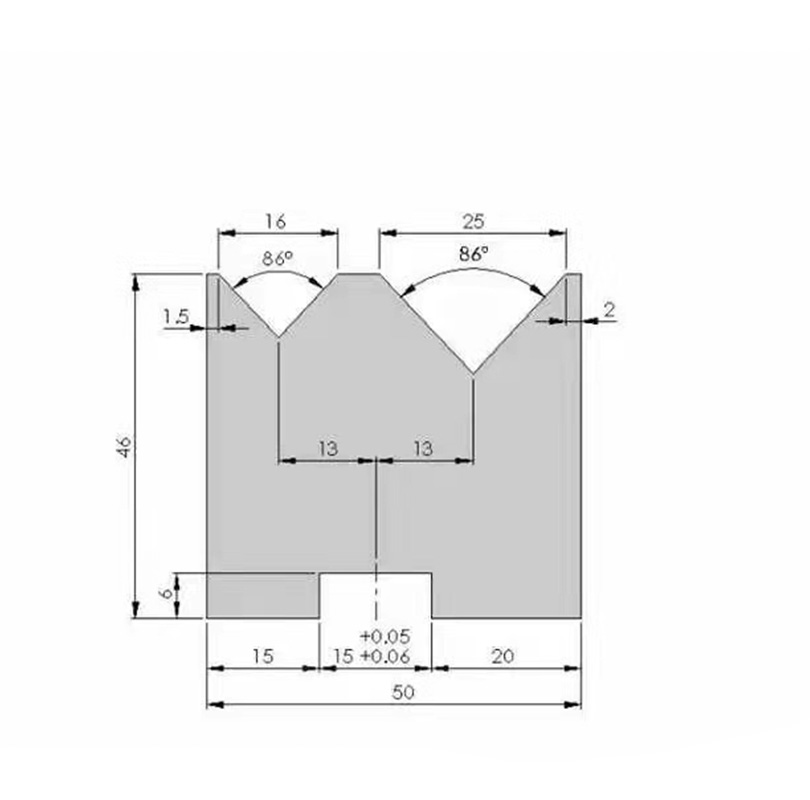

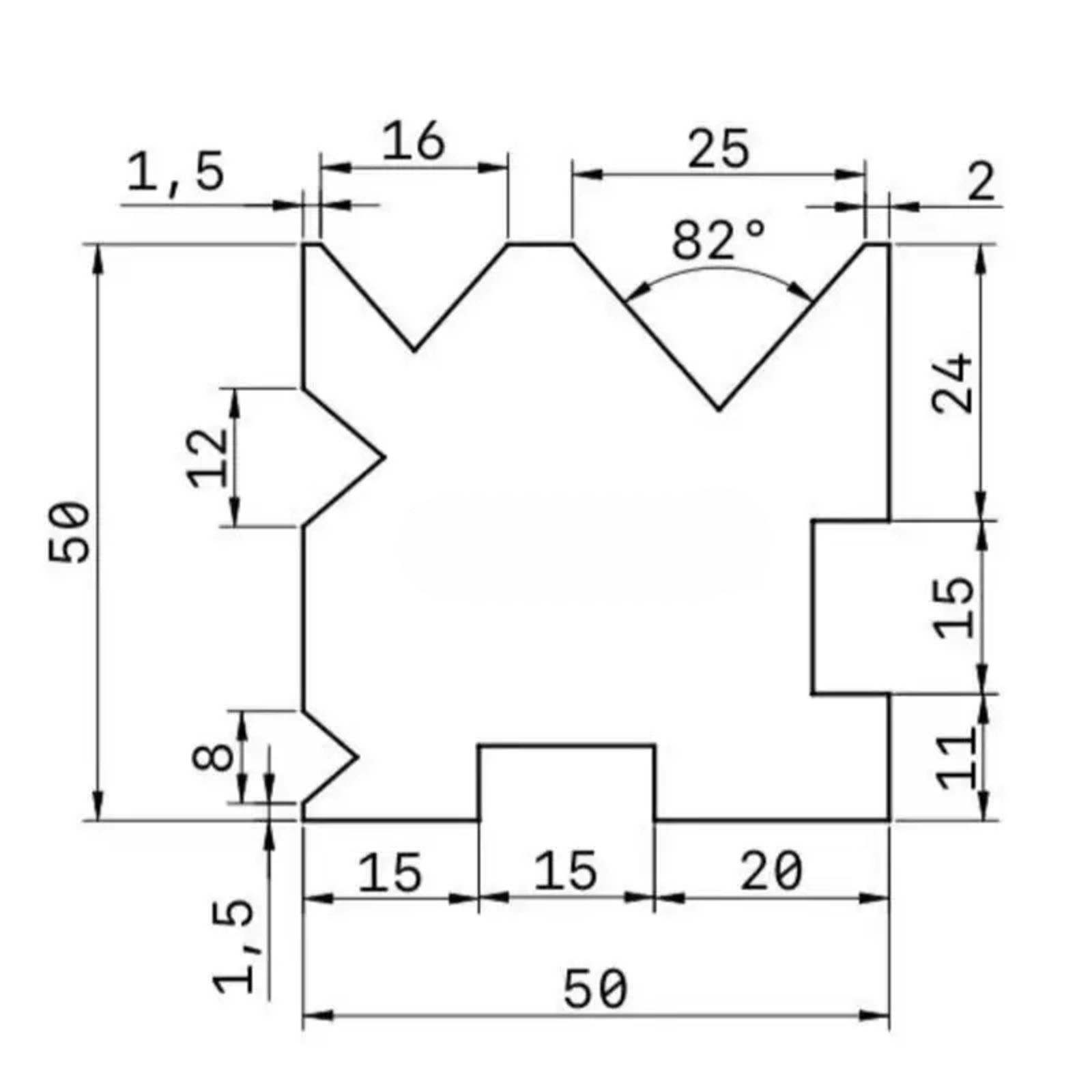

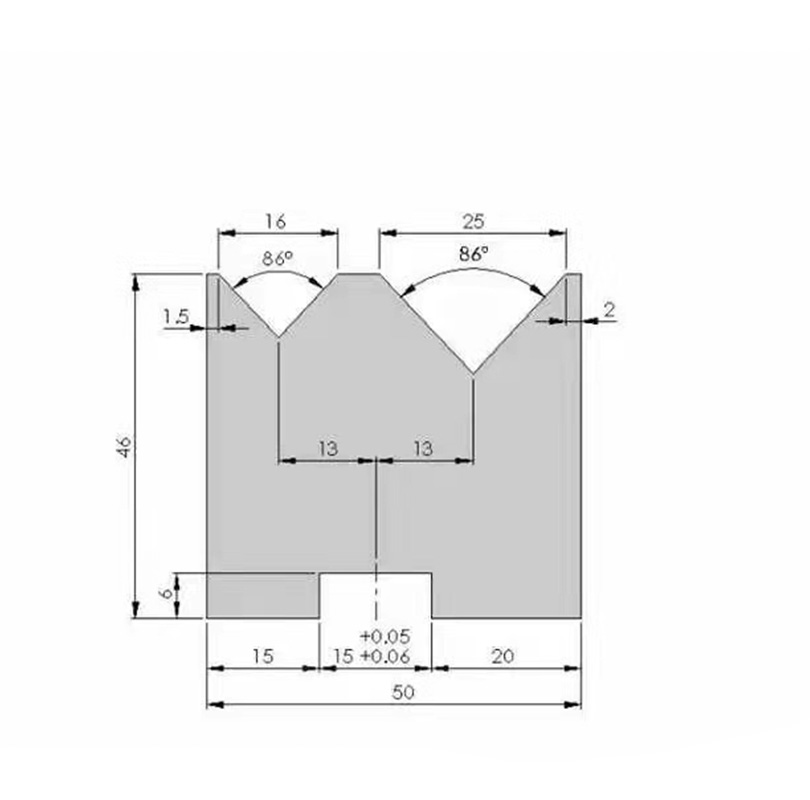

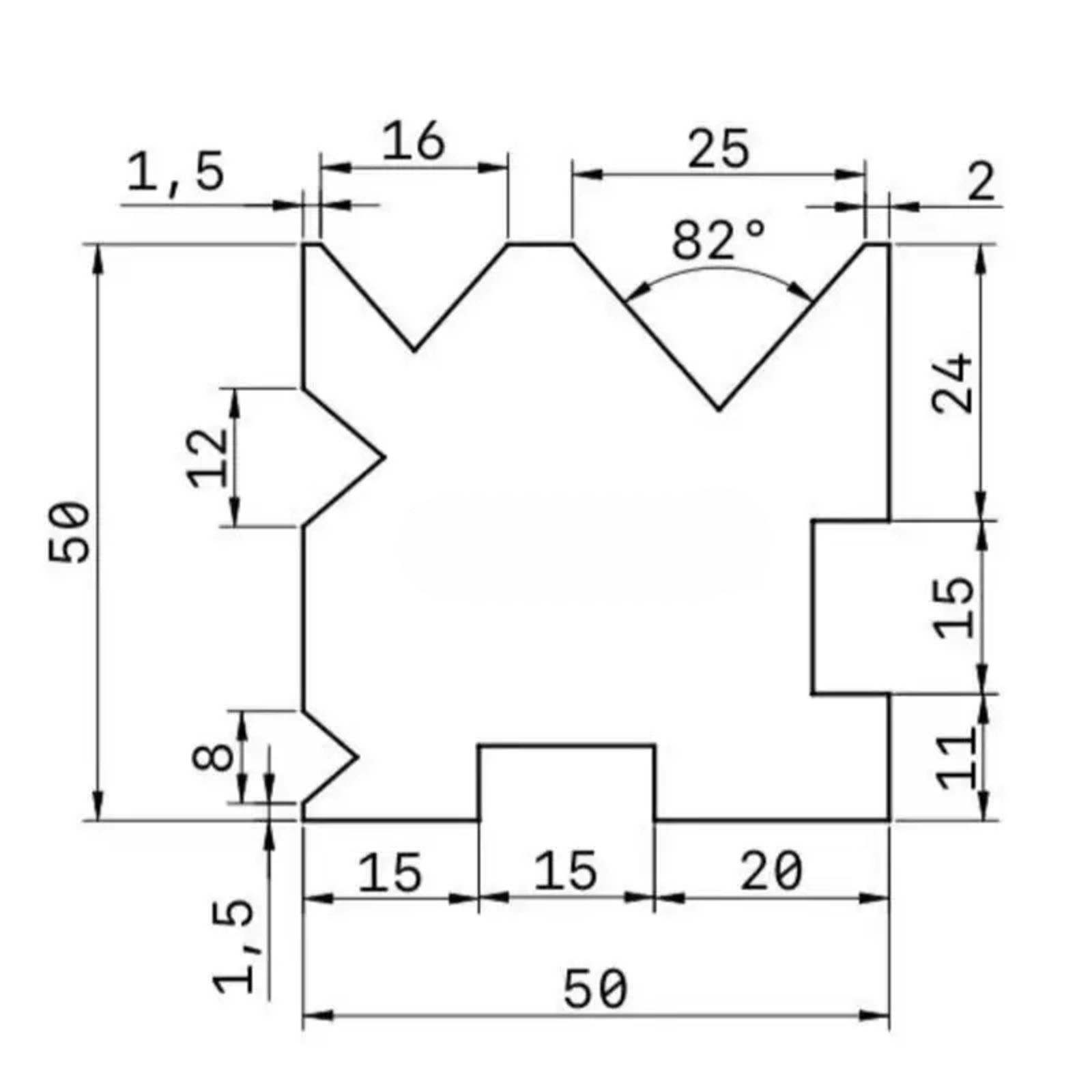

The selection of press brake tooling must first match the tensile strength and springback characteristics of the processed material, which is the core of ensuring accurate bending angles. Ordinary mild steel has minimal springback; when bending to 90°, an 86°~88° punch can be used for compensation. Stainless steel and high-strength steel have significant springback, requiring an 85° punch or targeted adjustment of the punch angle to avoid angular deviations of the workpiece after bending.

Material thickness directly determines the force-bearing condition and bending effect of the die. Thin, medium-thick, and thick materials require corresponding die specifications to avoid die damage or workpiece forming defects, meeting the needs of long-tail keyword searches such as "matching of material thickness and press brake tooling" on Google. The commonly used material for press brake tooling is 42CrMo, After tempering and surface induction hardening, its hardness typically reaches HRC 45-50. It has excellent strength and toughness, effectively preventing fracture under high pressure.and the following is its international standard comparison table.

The "8x Principle" is the core industry formula for bending machine die selection: "Lower die V-notch width V = 8 × material thickness T". As the optimal selection standard under ideal conditions, it is applicable to bending most medium-thick plates (3-8mm), ensuring smooth bending fillets and avoiding workpiece cracking.

Not all materials strictly follow the 8x Principle; the V-notch width needs to be flexibly adjusted according to material thickness: for thin plates (T<3mm), it can be reduced to V=6T to obtain a smaller fillet radius; for thick plates (T>8mm), it needs to be increased to V=10T~12T to reduce bending force, preventing die bursting and inner-side cracking of workpieces.

During selection, it is imperative to ensure that the die can withstand the actual output pressure of the bending machine; overloading is strictly prohibited, as it will cause die bursting and equipment damage. The calculation of pressure tonnage needs to combine material thickness, material tensile strength, and lower die V-notch width, and the die with corresponding bearing capacity should be selected after accurate calculation.

The actual output tonnage of the bending machine must be less than the rated bearing capacity of the die, with a certain safety margin reserved (10%-15% is recommended). For bending thick plates and high-strength steel, thickened dies or segmented dies should be selected to disperse bending pressure and extend die service life.

The punch shape must perfectly match the final shape of the workpiece to avoid interference or forming defects. Different punches correspond to different bending needs: standard punches are suitable for conventional straight-edge bending and have the widest application; sharp-angle punches are suitable for small-angle bending or springback compensation; gooseneck punches are suitable for processing U-shaped grooves and deep channels, as they can avoid the already bent edges of the workpiece.

For workpieces with circular or irregular shapes, arc punches or customized irregular punches should be selected. Combined with accurate workpiece drawings, the die contour must be completely matched with the workpiece to ensure bending forming accuracy.

The die shank type must be fully compatible with the clamping system of the bending machine. Common shank types include Amada/Promecam, New Standard, and Trumpf/Wila. The equipment clamping method should be confirmed before selection to avoid problems such as insecure die installation and positioning deviation.

The die height must match the slide stroke and worktable opening height of the bending machine. An excessively high die will lead to insufficient slide stroke, making it impossible to complete bending; an excessively low die will affect workpiece loading and unloading and reduce production efficiency. At the same time, the compatibility between the die installation interface and the equipment should be confirmed to ensure convenient installation and accurate positioning.

Country/Standard Organization | Standard Code | Corresponding Grade |

China (GB) | GB/T 3077 | 42CrMo or 42CrMo4 |

USA (AISI/ASTM) | ASTM A29 | 4140 |

International Organization for Standardization (ISO) | ISO 683-1 | 42CrMo4 |

Germany (DIN) | DIN EN 10083 | 1.7225 (or 42CrMo4) |

Japan (JIS) | JIS G4105 | SCM440 |

UK (BS) | BS 970 | 708M40 (EN19) |

press brake tooling are specialized forming molds used in conjunction with bending machines. They are the core working components for bending and forming metal sheets, mainly composed of two key parts: the upper die and the lower die. Through the relative movement of the bending machine's slider and workbench, the metal sheet is squeezed between the upper and lower dies, causing deformation and bending it into a workpiece of a specified angle, shape, and size (such as 90° right angle, U-shape, V-shape, etc.). They are widely used in sheet metal processing fields such as mechanical manufacturing, sheet metal fabrication, hardware production, and cabinet manufacturing.

: Installed on the movable slider of the bending machine, it is the active pressure-applying component. Its shape (standard straight edge, sharp corner, gooseneck, arc, etc.) determines the outer contour of the bent part of the workpiece;

: Fixed on the workbench of the bending machine, it is the fixed support component, mainly using a V-shaped groove (V-groove) as its structure. The width of the V-groove directly affects the bending force, fillet size, and forming effect of the sheet metal;

: The metal sheet is placed on the lower die, and the slider drives the upper die to press down vertically. The sheet is forced to conform to the contours of the upper and lower dies and undergoes irreversible plastic deformation. After reaching the preset stroke and pressure, the bending and forming are completed. After forming, the upper die returns to its original position, and the workpiece can be removed.

: The main material is alloy structural steel (such as 42CrMo), processed through heat treatment processes such as tempering and quenching, ensuring sufficient hardness (generally HRC45-HRC50), load-bearing capacity, and wear resistance to withstand the enormous extrusion force and friction during the bending process;

: According to the different bending requirements of the workpiece (angle, shape, size, material thickness), the punch can be customized into special shapes such as arc, gooseneck, and irregular shapes, and the die can be processed into V-grooves of different widths (such as 8mm, 16mm, 24mm) or special groove types;

: The specifications of the mold (height, shank type, installation size) must be fully compatible with the clamping system, slider stroke, and rated tonnage of the bending machine; the forming dimensions must be consistent with the workpiece drawing requirements to ensure bending accuracy and pass rate;

: Conventional bending machine molds have general standard specifications (matching common bending machine brands such as Amada, Trumpf, and Wille), and can be purchased and used directly; special molds can be customized according to the actual processing needs of the enterprise.

: Suitable for conventional straight edge bending, the most widely used;

: Suitable for small angle bending or springback compensation, meeting the needs of high-precision sharp angle forming;

: Suitable for U-shaped grooves and deep channel workpiece processing, which can avoid the already bent edges of the workpiece and prevent interference;

: Suitable for arc and rounded corner bending and forming, such as arc-shaped workpieces and transition rounded corner processing;

: Customized according to special workpiece drawings, suitable for bending requirements of irregular shapes.

: Suitable for ordinary sheet metals such as low-carbon steel and galvanized steel, offering high cost-effectiveness;

: Thickened design and high-hardness materials, suitable for difficult-to-bend materials such as stainless steel and high-strength alloy plates;

: Precision machined to prevent warping, deformation, and scratching during the bending of thin materials.

Amada/Promecam Type: Compatible with the clamping system of Amada series bending machines;

Trumpf/Wila Type: Compatible with the clamping system of Trumpf and Wila series bending machines;

New Standard Type: Universal interface, suitable for most domestic bending machines.

Selecting the right press brake tooling is crucial for ensuring bending accuracy, production efficiency, and die service life.

The key points for selecting press brake tooling are matching material characteristics, bending processes, workpiece requirements, and equipment parameters—none of which can be dispensed with. The following five key points cover all critical technical aspects of the entire selection process, ensuring both bending accuracy and die life. Beginners can directly refer to them for precise selection.

The selection of press brake tooling must first match the tensile strength and springback characteristics of the processed material, which is the core of ensuring accurate bending angles. Ordinary mild steel has minimal springback; when bending to 90°, an 86°~88° punch can be used for compensation. Stainless steel and high-strength steel have significant springback, requiring an 85° punch or targeted adjustment of the punch angle to avoid angular deviations of the workpiece after bending.

Material thickness directly determines the force-bearing condition and bending effect of the die. Thin, medium-thick, and thick materials require corresponding die specifications to avoid die damage or workpiece forming defects, meeting the needs of long-tail keyword searches such as "matching of material thickness and press brake tooling" on Google. The commonly used material for press brake tooling is 42CrMo, After tempering and surface induction hardening, its hardness typically reaches HRC 45-50. It has excellent strength and toughness, effectively preventing fracture under high pressure.and the following is its international standard comparison table.

The "8x Principle" is the core industry formula for bending machine die selection: "Lower die V-notch width V = 8 × material thickness T". As the optimal selection standard under ideal conditions, it is applicable to bending most medium-thick plates (3-8mm), ensuring smooth bending fillets and avoiding workpiece cracking.

Not all materials strictly follow the 8x Principle; the V-notch width needs to be flexibly adjusted according to material thickness: for thin plates (T<3mm), it can be reduced to V=6T to obtain a smaller fillet radius; for thick plates (T>8mm), it needs to be increased to V=10T~12T to reduce bending force, preventing die bursting and inner-side cracking of workpieces.

During selection, it is imperative to ensure that the die can withstand the actual output pressure of the bending machine; overloading is strictly prohibited, as it will cause die bursting and equipment damage. The calculation of pressure tonnage needs to combine material thickness, material tensile strength, and lower die V-notch width, and the die with corresponding bearing capacity should be selected after accurate calculation.

The actual output tonnage of the bending machine must be less than the rated bearing capacity of the die, with a certain safety margin reserved (10%-15% is recommended). For bending thick plates and high-strength steel, thickened dies or segmented dies should be selected to disperse bending pressure and extend die service life.

The punch shape must perfectly match the final shape of the workpiece to avoid interference or forming defects. Different punches correspond to different bending needs: standard punches are suitable for conventional straight-edge bending and have the widest application; sharp-angle punches are suitable for small-angle bending or springback compensation; gooseneck punches are suitable for processing U-shaped grooves and deep channels, as they can avoid the already bent edges of the workpiece.

For workpieces with circular or irregular shapes, arc punches or customized irregular punches should be selected. Combined with accurate workpiece drawings, the die contour must be completely matched with the workpiece to ensure bending forming accuracy.

The die shank type must be fully compatible with the clamping system of the bending machine. Common shank types include Amada/Promecam, New Standard, and Trumpf/Wila. The equipment clamping method should be confirmed before selection to avoid problems such as insecure die installation and positioning deviation.

The die height must match the slide stroke and worktable opening height of the bending machine. An excessively high die will lead to insufficient slide stroke, making it impossible to complete bending; an excessively low die will affect workpiece loading and unloading and reduce production efficiency. At the same time, the compatibility between the die installation interface and the equipment should be confirmed to ensure convenient installation and accurate positioning.

Country/Standard Organization | Standard Code | Corresponding Grade |

China (GB) | GB/T 3077 | 42CrMo or 42CrMo4 |

USA (AISI/ASTM) | ASTM A29 | 4140 |

International Organization for Standardization (ISO) | ISO 683-1 | 42CrMo4 |

Germany (DIN) | DIN EN 10083 | 1.7225 (or 42CrMo4) |

Japan (JIS) | JIS G4105 | SCM440 |

UK (BS) | BS 970 | 708M40 (EN19) |